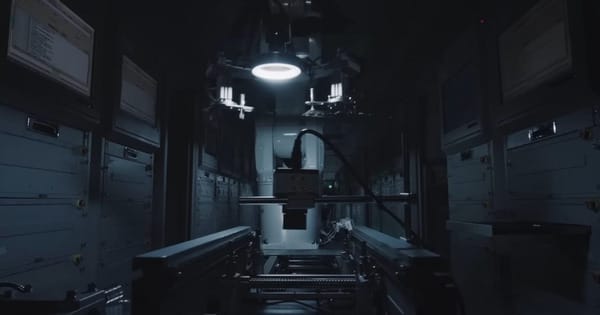

In today’s race toward smarter, faster, and more efficient production, a new concept is redefining the boundaries of industrial automation — the Dark Factory. Unlike traditional factories filled with workers, lights, and supervision, dark factories operate in near or total darkness — because they don’t need humans inside.

Powered by IoT (Internet of Things), AI (Artificial Intelligence), and robotics, these factories represent the ultimate stage of automation — where production continues 24/7 with minimal human intervention. But how exactly do they work? And how does IoT make this possible?

Contents

ToggleWhat Is a Dark Factory?

A Dark Factory is a fully automated manufacturing system where machines and digital systems handle every process — from material input to assembly, inspection, and packaging — without direct human presence.

The term “dark” reflects its independence from human needs such as lighting, HVAC, or shift changes. Instead, the factory runs autonomously, guided by real-time data and machine-to-machine communication.

Key Characteristics:

- No human operators on the floor

- Operates continuously 24/7

- Connected through IoT sensors and control systems

- AI-driven decision-making and optimization

- Integrated with MES, ERP, and SCADA systems for full visibility

In essence, a dark factory is not just a manufacturing plant — it’s a self-learning ecosystem.

The Role of IoT in Dark Factory Operations

At the heart of the dark factory is the IoT network — connecting every machine, conveyor, robot, and control unit into one intelligent infrastructure.

IoT transforms raw mechanical systems into data-driven entities capable of communicating, learning, and responding in real time.

1. Data Collection from the Shop Floor

Thousands of IoT sensors continuously monitor parameters such as:

- Temperature, humidity, vibration, torque, and energy consumption

- Machine performance, production rates, and product quality

- Environmental safety and predictive maintenance signals

Every movement, pressure, and operation is captured digitally.

2. Connectivity & Communication

Using industrial communication protocols (Ethernet/IP, OPC-UA, MQTT, or 5G), IoT devices send data to centralized gateways.

These gateways synchronize information with edge servers and cloud platforms, ensuring seamless communication between machines and systems.

3. Edge & Cloud Intelligence

IoT data is analyzed by:

- Edge computing for instant, local decision-making (e.g., stop a malfunctioning machine).

- Cloud AI systems for long-term insights — predicting maintenance needs, optimizing scheduling, and analyzing efficiency patterns.

4. Automation Feedback Loop

Once analysis is complete, the system automatically adjusts:

- Machine speed, pressure, or temperature

- Material flow and robot pathing

- Production schedules and energy usage

This closed-loop automation enables continuous improvement without human involvement.

Key Technologies That Enable Dark Factories

| Technology | Role in Automation |

|---|---|

| IoT Sensors & Gateways | Data collection and connectivity |

| Robotics & Cobots | Automated assembly, handling, and logistics |

| AI & Machine Learning | Predictive decision-making and optimization |

| SCADA / MES / ERP Integration | Real-time monitoring and business synchronization |

| Digital Twins | Simulate and optimize factory operations virtually |

| 5G & Edge Computing | High-speed, low-latency communication for real-time control |

Together, these technologies create a fully autonomous production loop, capable of learning and improving performance over time.

Benefits of IoT-Powered Dark Factories

- Continuous Operation 24/7: No downtime for shifts or breaks — machines work around the clock, increasing throughput and ROI.

- Higher Precision and Quality: IoT-driven monitoring ensures every product meets consistent standards, with AI detecting even micro-level defects.

- Reduced Costs and Energy Usage: By eliminating human dependency and optimizing energy consumption, manufacturers achieve up to 30–40% cost savings.

- Predictive Maintenance: IoT sensors detect anomalies early, allowing proactive maintenance before failures occur — reducing downtime by 40–60%.

- Sustainability and ESG Compliance: Smart monitoring systems track resource usage and emissions, helping companies reduce CO₂ footprints and achieve sustainability goals.

Real-World Examples of Dark Factories

FANUC (Japan)

One of the most advanced examples — FANUC’s “lights-out” factory runs for 30 days continuously without human workers, producing industrial robots autonomously.

Philips (Netherlands)

Philips’ razor factory operates almost entirely with robots, where only a few engineers monitor the process remotely.

Tesla Gigafactory

Tesla’s manufacturing facilities use IoT and AI-driven systems to coordinate robotic production lines, predictive maintenance, and logistics.

From Smart Factory to Dark Factory: The Evolution

| Stage | Description | Human Role |

|---|---|---|

| Automation Factory | Basic robotic and programmable control | Manual supervision |

| Smart Factory | Connected systems via IoT & AI | Operator assistance |

| Dark Factory | Fully autonomous, data-driven operations | Remote oversight only |

This evolution shows the gradual shift from manual control to autonomous intelligence — where human effort moves from repetitive tasks to strategic innovation.

Challenges of Implementing a Dark Factory

Despite its promise, the journey toward a fully automated plant isn’t simple.

1. High Initial Investment

Building a dark factory requires substantial costs for IoT infrastructure, robotics, and AI integration.

2. Cybersecurity Risks

With thousands of connected devices, data security becomes critical to avoid breaches and downtime.

3. Skill Gap

Organizations must retrain employees for data analytics, AI operations, and remote system management.

4. Integration Complexity

Synchronizing legacy machines with IoT systems and cloud platforms requires robust architecture design.

The Future: Industry 5.0 and Human–Machine Collaboration

While dark factories highlight automation’s potential, Industry 5.0 shifts the focus from total replacement to human–machine collaboration.

IoT and AI handle data-driven precision, while humans contribute creativity, ethics, and innovation.

Future factories will therefore not be “dark” in the sense of excluding humans, but “intelligent” — blending automation with human insight for sustainable, adaptive production.

Conclusion: IoT as the Brain of the Dark Factory

The Dark Factory represents the ultimate achievement of Industry 4.0 — where IoT connects, AI analyzes, and automation executes.

It is the factory that never sleeps, powered by data and intelligence rather than human labor.

For manufacturers aiming to modernize, the path begins with IoT connectivity, leading to smart automation, and ultimately, a self-sustaining ecosystem that defines the future of industrial efficiency.

Ready to Build Your Smart or Dark Factory?

At Dev Station Technology, we design and implement IoT-enabled automation solutions tailored for manufacturing environments.

From predictive maintenance to full-factory digitization, we help you take control of your production data — securely, efficiently, and intelligently.

🔗 Contact our IoT specialists today to explore your path toward the next generation of manufacturing:

👉 dev-station.tech/contact

📧 sales@dev-station.tech