Client: A Forward-Thinking Poultry Collective

Industry: Agriculture, Livestock Farming

Challenge: To increase operational efficiency, improve flock health, and meet rising demands for food safety and traceability in harsh barn environments.

Contents

ToggleExecutive Summary

Dev Station Technology has deployed a comprehensive, end-to-end IoT solution that empowers modern poultry farms to move from reactive manual checks to proactive, data-driven management. By integrating rugged wireless sensor nodes with a powerful cloud dashboard and an intuitive mobile app, our platform delivers real-time insights into critical environmental parameters. This enables farm managers to optimize resource usage, receive early warnings of potential hazards like CO₂/NH₃ spikes, and ultimately improve both yield and profitability. The solution is built on standards-based hardware, ensuring a low total cost of ownership (TCO) and seamless scalability from a single barn to a multi-farm enterprise.

The Challenge: Navigating the Complexities of Modern Poultry Farming

Our partners faced a series of pressing challenges common across the industry:

Harsh Operating Conditions: Barn environments are hostile to electronics, with high levels of dust, humidity, and ammonia, plus frequent high-pressure disinfection cycles. Equipment must be exceptionally durable.

Lack of Real-Time Visibility: Manual, periodic checks of temperature, humidity, and flock behavior were inefficient and often too late to prevent issues like heat stress or poor air quality, which directly impact growth and mortality rates.

Rising Operational Costs: Inefficient management of ventilation, heating, and feeding systems led to wasted energy and resources, squeezing already tight profit margins.

Increasing Regulatory & Consumer Demands: A growing need for complete traceability and verifiable data on animal welfare required a shift from paper-based logs to a robust digital system.

Scalability Constraints: Traditional wired monitoring systems were expensive, difficult to install, and inflexible, making it challenging to expand operations row by row or barn by barn.

The Solution: The Dev Station Tech Smart Farm Platform

Dev Station Tech engineered a turnkey solution addressing every challenge head-on. The architecture consists of three core components:

1. Rugged, Intelligent Sensor Nodes (DST-Agri Node)

Built on the proven ESP32 platform, our nodes are designed for the toughest conditions:

Comprehensive Monitoring: Each node tracks key parameters: Temperature, Humidity, CO₂ (NDIR), NH₃ (Ammonia), light, and even flock activity via acoustic sensors.

Extreme Durability: Housed in IP66-rated polycarbonate enclosures, the nodes are resistant to dust, water jets, and frequent disinfection.

Smart Power Management: An advanced deep-sleep mode allows nodes to operate for 6-18 months on a single battery charge, virtually eliminating the need for complex wiring and minimizing maintenance. They can also be powered by small solar panels or a 24VDC line.

2. Flexible Connectivity & Edge Gateway

We ensure data is never lost, regardless of on-site connectivity:

Adaptive Wireless Network: The system intelligently uses Wi-Fi/ESP-Mesh for robust coverage in dense layouts and the power-efficient ESP-NOW protocol to send critical data bursts from nodes to the gateway, even in obstructed areas.

Uninterrupted Data Flow: An on-site Edge Gateway (4G/Ethernet) aggregates data from all nodes. Its local buffering capability ensures that if cloud connectivity is lost, data is stored securely and automatically synced once the connection is restored.

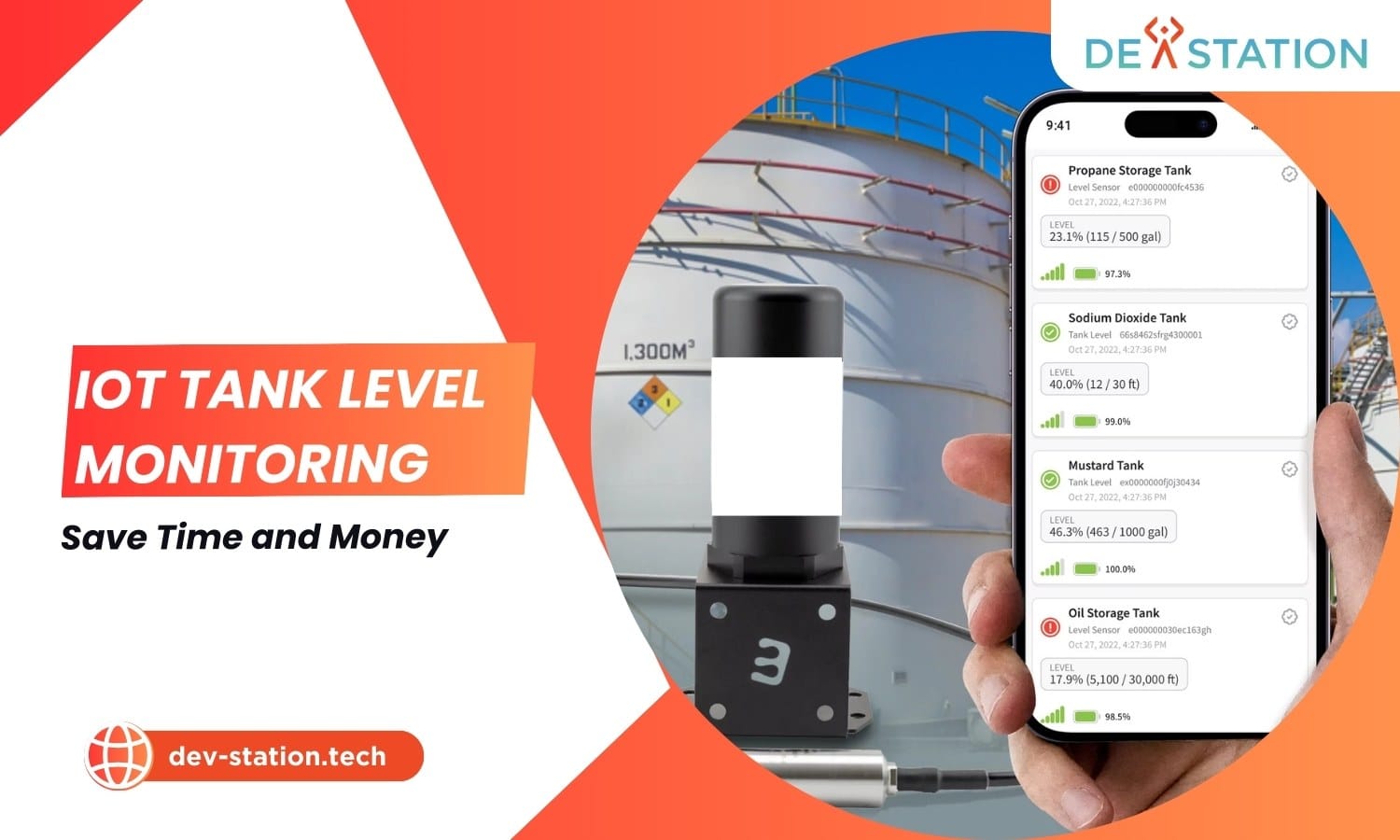

3. Powerful Cloud Platform & Intuitive Mobile App

This is the central nervous system of the farm, turning raw data into actionable intelligence:

Centralized Command Center (As seen in the video): The ThingsBoard-powered dashboard provides a holistic view of all farms and zones (e.g., specific barns, rows, or pens). Managers can monitor key metrics, view weather forecasts, and receive smart suggestions.

Full Remote Control: The “Smart Farm” mobile app allows managers to drill down into specific zones, such as “Chicken farm 1,” and remotely control devices like fans, heaters, lights, and automated feeders with a simple tap.

Proactive Alerts: Customizable thresholds trigger multi-channel alerts (SMS, Email, Telegram) to notify the right personnel the moment a parameter like CO₂ or humidity deviates from the optimal range.

The Results: Tangible Business Outcomes

The deployment of the Dev Station Tech platform delivered immediate and significant value:

90% Reduction in Manual Environmental Checks: Freed up staff to focus on higher-value tasks related to animal health and husbandry.

Rapid & Non-Disruptive Deployment: A standardized rollout process meant a cluster of 4-6 barns was fully operational in just 2-4 days, with each node installed and commissioned in under 3 minutes.

Improved Flock Health & Reduced Mortality: Early warnings on poor air quality allowed for immediate ventilation adjustments, preventing respiratory issues and heat stress.

Data-Driven Cost Optimization: By correlating environmental data with feed/water intake and energy consumption, management made informed decisions that directly reduced operational costs.

Enhanced Traceability: A complete, immutable digital record of batch conditions was automatically generated, ready for regulatory audits or buyer verification.

“The ESP nodes from Dev Station Tech stand up well to dust and humidity and are configured in minutes on a phone. When CO₂ climbs, the system automatically ramps the fans and alerts the shift to keep the flock stable. It’s moved us from guessing to knowing.”

– Operations Manager at a Pilot Farm

Why Dev Station Tech?

Low Total Cost of Ownership (TCO): We use industry-standard components, eliminating vendor lock-in and ensuring spare parts are affordable and readily available.

Future-Proof Scalability: Our architecture is designed to grow with your business. Adding a new row or an entire barn is as simple as deploying new nodes.

Focus on Security & Reliability: With end-to-end TLS encryption, secure over-the-air (OTA) updates, and offline data buffering, your data and operations are always safe.

Forward-Thinking Roadmap: We are continuously innovating, with developments in Edge AI for early disease detection and full ERP/Odoo integration for seamless farm-to-enterprise data flow.

The same robust architecture is adaptable beyond poultry to swine, dairy, aquaculture, and greenhouse operations.

Ready to bring data-driven intelligence to your agricultural operations?

Contact US to schedule a demo and discover how Dev Station Tech can optimize your farm for the future.

Email: sales@dev-station.tech

Web: dev-station.tech