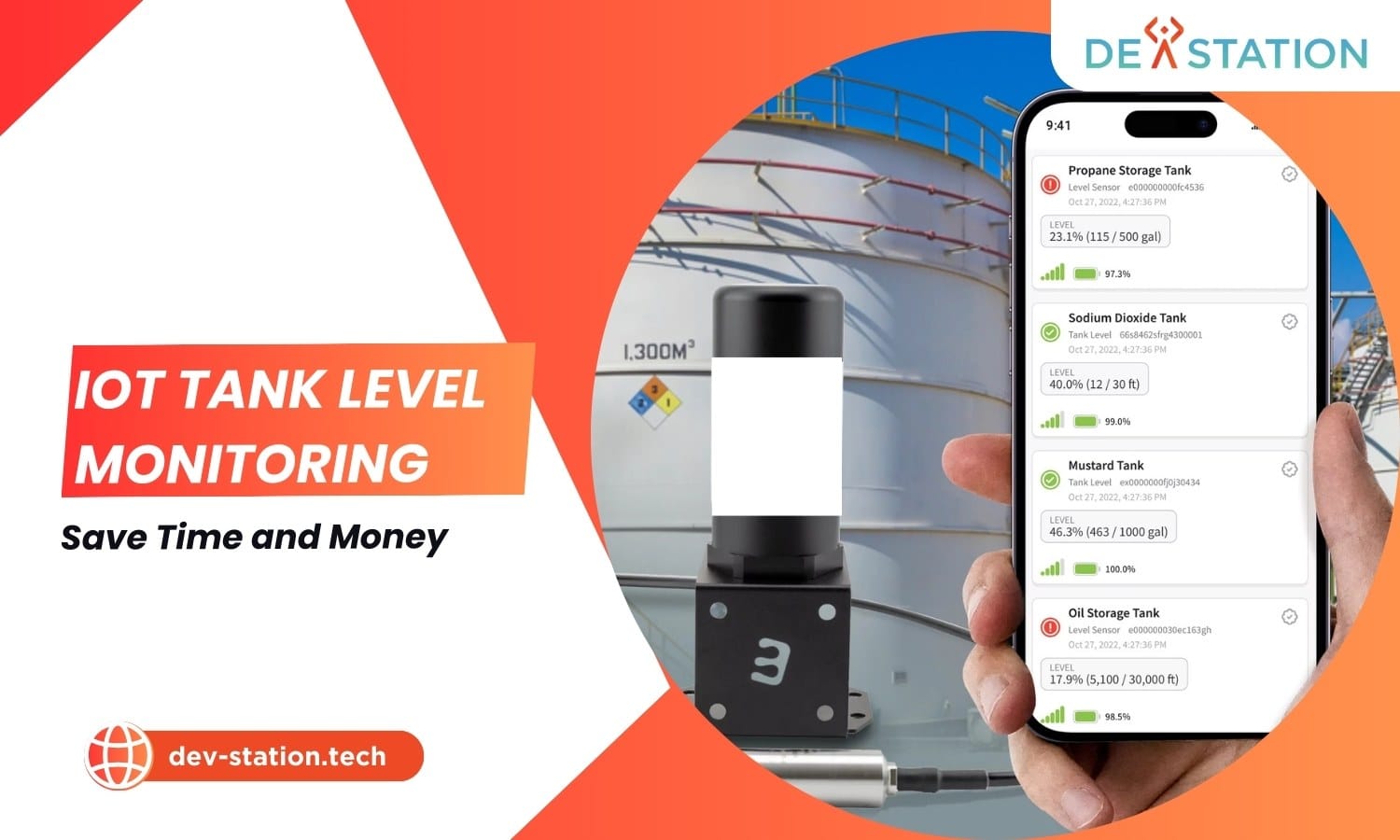

IoT tank level monitoring provides a smarter way to manage your liquid assets, offering real-time data and automated alerts to prevent costly issues and streamline operations. At Dev Station Technology, we engineer advanced remote fluid level monitoring solutions that transform how businesses handle their bulk liquid inventory, ensuring efficiency and reliability. Explore our automated tank measurement systems, smart tank gauging technology, and advanced sensor networks.

Contents

ToggleHow Can IoT Tank Level Monitoring Save Your Business Time and Money?

IoT-based tank level monitoring delivers substantial savings by automating manual tasks, preventing expensive incidents like spills and shortages through real-time data, and optimizing supply chain logistics for maximum efficiency. This technology shifts your operations from a reactive to a proactive model, directly boosting your bottom line.

For any business managing bulk liquids—be it in agriculture, oil and gas, chemical manufacturing, or water management—tanks are critical assets. However, traditional management methods are notoriously inefficient and fraught with risk. The adoption of smart tank gauging is not just an upgrade; it is a fundamental strategic shift that generates a significant return on investment through three primary avenues: labor cost reduction, incident prevention, and logistical optimization.

How Does Automated Monitoring Eliminate Manual Checks?

By providing continuous, remote data access, automated monitoring completely removes the need for employees to physically visit and inspect tanks. This directly translates into significant labor cost savings and frees up personnel for higher-value activities.

Manual tank gauging is a time-consuming and often hazardous process. It requires employees to travel to tank locations, which may be remote or difficult to access, climb ladders, and use dipsticks or other manual tools to measure levels. This process is not only inefficient but also introduces risks of human error and workplace accidents. An iot remote monitoring system automates this entire workflow.

Detailed Calculation of Labor Savings:

Let’s create a conservative scenario for a business with 20 tanks that require weekly manual checks.

- Time per Check: Assume it takes an average of 30 minutes (0.5 hours) per tank, including travel time between tanks and the measurement itself.

- Total Time per Week: 20 tanks * 0.5 hours/tank = 10 hours per week.

- Average Labor Cost: Assuming a loaded labor cost (including wages, benefits, and overhead) of $40 per hour.

- Weekly Cost of Manual Checks: 10 hours * $40/hour = $400 per week.

- Annual Cost of Manual Checks: $400/week * 52 weeks = $20,800 per year.

By implementing an IoT solution, this business could save over $20,000 annually in direct labor costs alone. This frees up 520 man-hours that can be reallocated to more productive tasks, such as maintenance, quality control, or customer service, further enhancing operational value.

How Does Real-Time Data Prevent Costly Spills and Shortages?

Real-time data and automated alert notifications act as a 24/7 watchdog for your tanks. They provide immediate warnings for critically high or low levels, allowing you to take preventative action before a costly overflow or a production-halting shortage occurs.

The financial consequences of a tank overflow or an unexpected stockout can be catastrophic.

- Overflows and Spills: These incidents lead to the loss of valuable product, expensive cleanup costs, potential environmental fines, and damage to your company’s reputation. According to the EPA, the cleanup cost for even a moderately sized industrial spill can range from hundreds of thousands to millions of dollars.

- Shortages and Stockouts: An unexpected depletion of a critical liquid can bring operations to a complete standstill. In manufacturing, this means idle machinery and lost production. In agriculture, it could mean the inability to irrigate crops or provide water for livestock, leading to significant financial losses.

IoT tank monitoring systems mitigate these risks through continuous, automated oversight. You can configure custom thresholds for each tank. When a level exceeds a high-level limit or drops below a critical low-level point, the system automatically triggers alerts sent via SMS, email, or a mobile app. This allows your team to intervene immediately, whether it is by shutting off a pump to prevent an overflow or scheduling an emergency delivery to avert a stockout.

How Can Data-Driven Insights Optimize Your Supply Chain?

By transforming raw level data into historical usage patterns and predictive forecasts, IoT platforms allow you to implement just-in-time refills and optimize your entire supply chain. This reduces carrying costs, minimizes transportation expenses, and enhances overall operational agility.

Without accurate, real-time data, inventory and delivery scheduling is based on guesswork and historical estimates. This often leads to inefficient practices like a fixed delivery schedule, regardless of actual consumption. Such methods result in wasted trips, where trucks are sent to refill tanks that are still mostly full, or panic-driven emergency deliveries at a premium cost. IoT solutions provide the detailed data logging necessary for intelligent supply chain management.

The system collects and stores historical data on each tank’s consumption rate. By applying analytics to this data, you can:

- Predict Future Needs: The platform can accurately forecast when a tank will need a refill, moving you from a reactive to a predictive model.

- Optimize Delivery Routes: Logistics planners can view the real-time status of all tanks on a map, allowing them to create the most efficient delivery routes that service only the tanks that actually need it.

- Implement Just-in-Time (JIT) Inventory: By ordering refills only when needed, you reduce the amount of capital tied up in stored product and lower your overall inventory management costs. Studies have shown that IoT-driven supply chains can reduce inventory holding costs by 10-20%.

What Exactly Is an IoT Tank Level Monitoring System?

An IoT tank level monitoring system is an integrated solution that uses sensors to measure the amount of a substance in a tank, a gateway to transmit that data, and a cloud platform to process and display the information. It provides users with remote, real-time access to tank levels and automated alerts.

Think of it as a smart, connected gauge for your tanks. Unlike traditional sight glasses or manual dipsticks, an IoT-based system provides continuous, accurate, and remotely accessible data without needing anyone to be physically present. This technology is a cornerstone of modern industrial automation and is crucial for efficient resource management in sectors like iot in agriculture and water management.

What Are the Core Components of This Technology?

The system is comprised of four key layers: the sensor, which measures the level; the gateway, which collects and transmits data; the cloud platform, which processes and stores the data; and the user application, where you view dashboards and receive alerts.

| Component | Function | Common Technologies |

|---|---|---|

| Sensor | Physically measures the distance to the liquid’s surface inside the tank. | Ultrasonic, Radar, Hydrostatic, Lidar |

| Gateway/Node | A battery- or solar-powered device that reads the sensor data and transmits it wirelessly to the cloud. | Cellular (4G/5G, NB-IoT), LoRaWAN, Satellite |

| Cloud Platform | Receives, processes, and stores the data. It runs the logic for alerts and analytics. | AWS IoT, Microsoft Azure IoT, Cumulocity |

| User Application | A web dashboard or mobile app where you can view current levels, historical trends, and manage alert settings. | Web Browser, iOS/Android App |

How Can You Find the Right IoT Tank Level Monitoring Vendor?

Finding the right vendor involves evaluating their industry experience, the reliability and suitability of their hardware for your specific liquid and environment, the scalability of their software platform, and the quality of their technical support.

Choosing a partner for your remote tank monitoring solution is a critical decision. The market contains a wide range of providers, from hardware manufacturers to full-service platform providers. According to Gartner’s Magic Quadrant for Industrial IoT Platforms, leaders in the space like Microsoft, AWS, and Software AG provide robust and scalable platforms that are often leveraged by solution providers.

What Factors Should You Consider When Choosing a Solution?

Key factors include the sensor’s compatibility with your product, the connectivity options for your locations, the software’s ease of use and integration capabilities, and the total cost of ownership over the long term.

- Sensor Technology: Is the sensor appropriate for your liquid? For example, non-contact ultrasonic sensors are great for water and many chemicals but are not ideal for foamy liquids or gasoline, which may require radar or hydrostatic sensors.

- Connectivity: Does the vendor offer connectivity options that work for your tank locations? LoRaWAN is excellent for low-power, long-range applications in rural areas where you can set up a private network, while NB-IoT or Cellular is better for urban areas with existing network coverage.

- Platform Scalability: Can the software platform handle your future growth? Look for a platform that can support an increasing number of devices and integrate with other business systems via APIs.

- Hardware Durability: Will the device withstand your environment? Ensure the sensor and gateway have the appropriate IP rating for dust and water protection and can operate within your location’s temperature range.

- Total Cost of Ownership (TCO): Look beyond the initial hardware price. Consider ongoing software subscription fees, data plan costs, and potential maintenance expenses.

Why Should You Partner with Dev Station Technology?

Dev Station Technology provides robust, end-to-end IoT solutions tailored to your specific industry needs. We combine reliable hardware, a powerful and intuitive software platform, and expert support to ensure you get a solution that delivers maximum ROI.

At Dev Station Technology, we understand that an IoT solution is more than just hardware. We work with you to analyze your operational needs and design a complete system that seamlessly integrates into your workflow. Our platform offers advanced analytics, customizable dashboards, and powerful alert configuration to put you in complete control of your assets. Contact us to learn how our smart solutions can transform your business.

Is It Possible to Build a DIY IoT Tank Level Monitoring System?

Yes, for technically inclined users, building a DIY system is an achievable and rewarding project. It offers maximum customization and can be a cost-effective solution for smaller-scale deployments, though it requires knowledge of hardware, firmware, and software.

For those who enjoy a hands-on approach, building your own iot-based tank level monitoring system can be a great way to get a fully customized solution. This path is popular for smart farming applications, home rainwater tank monitoring, or small-scale industrial use where commercial solutions might be overkill. Numerous online communities and tutorials provide guidance for these types of projects.

What Are the Basic Steps for a DIY Setup?

A typical DIY project involves selecting a microcontroller like an ESP32, choosing an appropriate sensor, writing the firmware to read the sensor and transmit data, and connecting it to an IoT platform for visualization.

- Choose a Microcontroller: The ESP32 is a popular choice because it is inexpensive, powerful, and has built-in Wi-Fi and Bluetooth connectivity.

- Select a Sensor: A waterproof ultrasonic sensor like the JSN-SR04T or AJ-SR04M is a common starting point for measuring water levels. These sensors work by sending out a sound pulse and measuring the time it takes for the echo to return, which can be converted to distance. Good sensors can achieve an accuracy of 0.1–1% under ideal conditions.

- Write the Firmware: Using a framework like the Arduino IDE or ESPHome, you will write code to read the distance from the sensor, convert that distance into a tank volume or percentage, and send the data over Wi-Fi using the MQTT protocol.

- Connect to a Platform: You can send your data to an open-source IoT platform like ThingsBoard or a service like Ubidots. These platforms provide the tools to create dashboards, store historical data, and set up alert rules without needing to build a cloud backend from scratch.

- Power and Housing: Finally, you’ll need to consider a power source (like a battery with a solar panel for remote locations) and a weatherproof enclosure to protect the electronics.

Whether you are looking for a fully managed, enterprise-grade solution or guidance on a custom project, Dev Station Technology has the expertise to help you leverage the power of IoT. Our solutions provide the reliability, scalability, and data insights you need to save time, reduce costs, and optimize your operations.

Take control of your valuable liquid assets today. Visit us at dev-station.tech or contact our team of experts at sale@dev-station.tech to learn more and schedule a consultation.